Farasis Energy (Ganzhou) Co., Ltd. (Stock Code: 688567.SH), founded in 2009, focuses on the R&D, manufacturing, and sales of power battery systems for new energy vehicles (NEVs) and energy-storage systems, providing leading, green solutions for global new-energy applications.

Its core pouch-cell power batteries offer outstanding performance, featuring high energy density, strong safety, long cycle life, fast charging, and wide temperature adaptability.

As one of the world’s leaders in pouch power batteries, Farasis Energy ranked in the global Top 8 for power-battery installations in 2023, has remained in the global Top 3 for pouch-battery installations for many years, and has held the No.1 position in China for pouch-battery installations for eight consecutive years (2017–2024).

Farasis Energy is accelerating toward a digital and intelligent future. By building a unified data platform, the company plans a comprehensive upgrade of its IT systems to form a powerful “data-intelligent brain” that enables more efficient, data-driven decision-making. In this transformation, YMatrix—thanks to its superior data processing capabilities and performance—has become a key partner, helping Farasis Energy consolidate and analyze data at scale and laying a solid digital foundation for smart manufacturing.

While many traditional manufacturers still struggle to capture production-line data and tune parameters, Farasis Energy has built advanced digital lines where every process and inspection becomes traceable, queryable digital assets.

Now, Farasis Energy is investing to upgrade the group’s entire data foundation and application stack. Centered on a unified data platform, the goal is to govern and leverage hundreds of terabytes of existing data and to build a “data-intelligent brain” spanning R&D, production, and global operations.

Support end-to-end data across all factors of production and operations—from analysis, design, project initiation, R&D, manufacturing, and management to O&M services—covering data ingestion, cleansing, governance, application, analytics, and mining. Achieve full data-lifecycle visibility, control, and compliance. Align with automotive and new-energy industry standards to support lifecycle traceability, improve efficiency, meet regulatory and production needs, and enable rapid data mining and deep analytics to raise overall production efficiency and business outcomes.

Adopt new-generation IT—componentization, microservices, and cloud architecture—to build a global PLM platform. Define global operational processes and construct a modern technical architecture. With a “small tools, big impact” strategy, deliver more efficient, stable, and flexible services across departments, boosting product management, innovation, and R&D efficiency.

Establish a unified global data-operations platform and integrated multi-region cloud services. Standardize business processes and data to enhance consistency and efficiency, better support overseas operations, extend high-quality customer services, and empower subsidiaries—elevating group-wide collaboration.

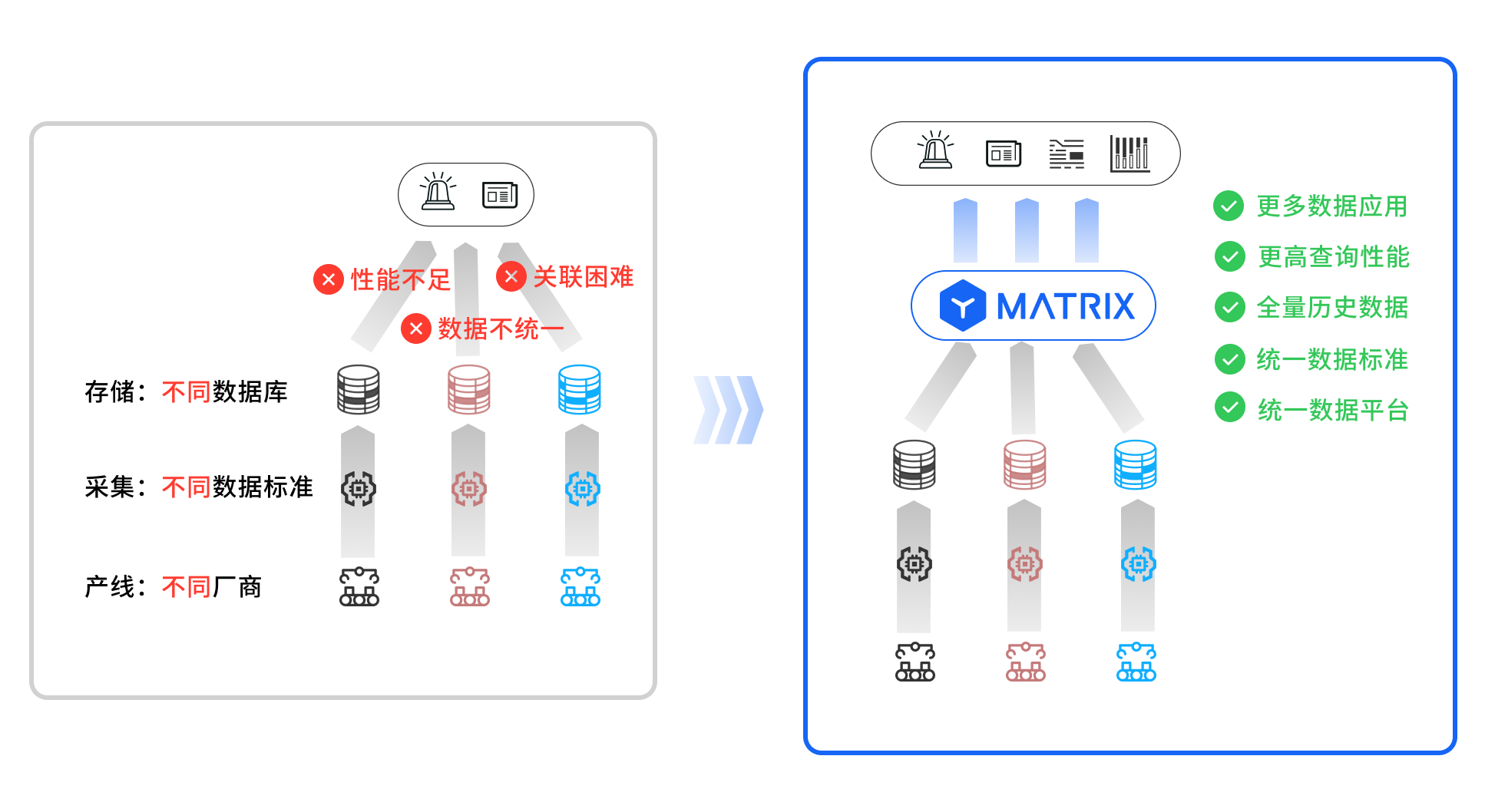

Taking the power-battery traceability system as a catalyst, Farasis Energy planned to modernize its fragmented database estate—previously spanning Oracle, SQL Server, MySQL, and more—into a next-generation, one-stop data infrastructure for the group.

In this vision of a “data-intelligent brain,” a powerful, unified data foundation is the bedrock.

To this end, Farasis Energy initiated a data lakehouse program. It integrates heterogeneous business data sources—supporting full, incremental, batch, real-time synchronization, plus monitoring and alerting. With lakehouse storage and a unified streaming-and-batch analytics engine, the platform handles petabyte-scale, multi-model data; supports both streaming and batch processing; and serves analytics, data science, and more—delivering one-stop data exploration and development.

In 2018, seven Chinese ministries (including MIIT, MOST, and MEE) issued the Interim Measures for the Management of Recycling of Power Batteries for New Energy Vehicles, establishing a traceability platform and requiring end-to-end data collection across production, sales, usage, scrapping, recycling, and reuse.

Building compliant traceability hinges on data integration—and that’s the biggest challenge.

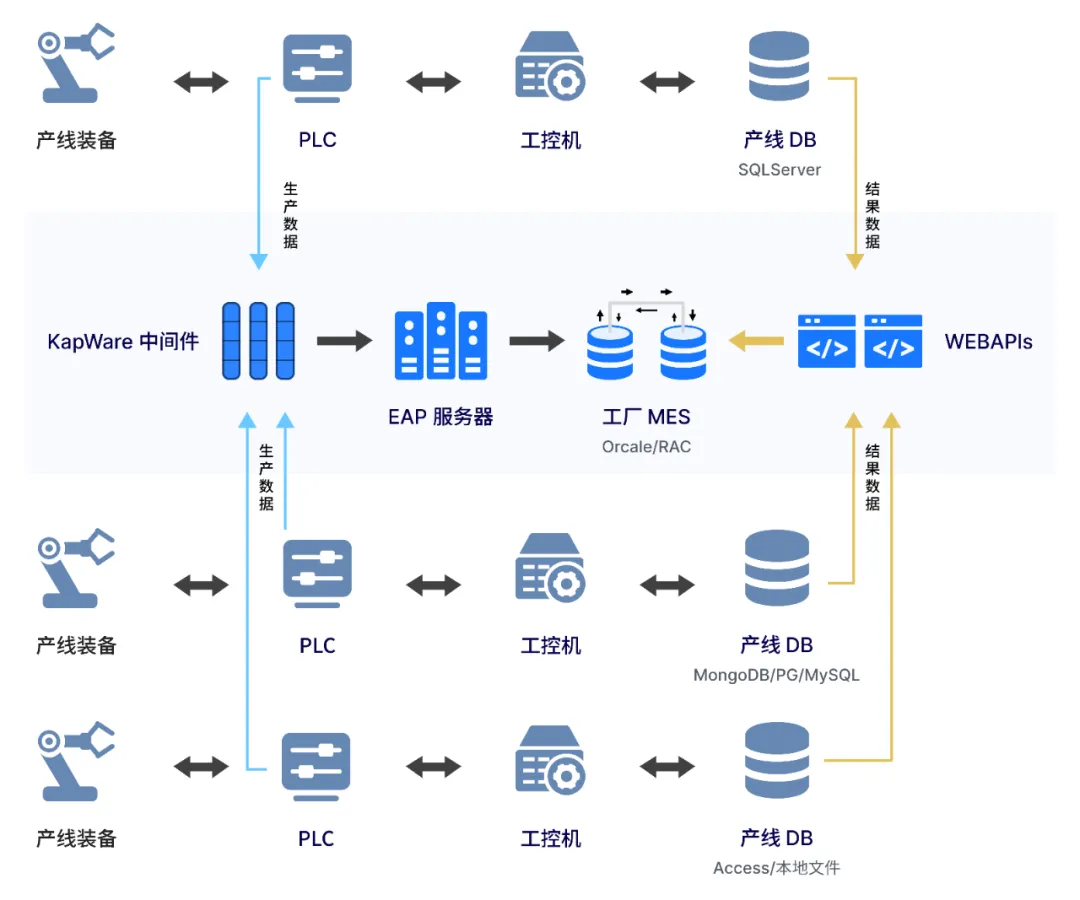

First, data aggregation at factory scale is hard, and production lines generate massive volumes. With equipment and solutions sourced from multiple vendors, data standards vary widely. Downstream cleansing and standardization are needed to produce high-quality, unified data—further raising the bar for the underlying infrastructure’s ingest, storage, and compute capabilities.

Second, traceability queries are not simple point lookups. They require joins across multiple, very large tables—some with tens of billions of rows. Under such volumes, excellent performance on complex queries becomes a decisive requirement for the data platform.

Finally, elasticity and cost matter. Rapid data growth demands strong compression to lower storage costs; as production expands and applications proliferate, elastic scaling of storage and compute is critical.

Together, these formed Farasis Energy’s hard requirements for database selection.

During pre-research, the team trialed several data-platform products to stand up an initial system. While some queries were only passable, the results met baseline needs. After learning more about YMatrix’s strengths in time-series and analytics warehousing—functionality, performance, and cost—Farasis Energy ran an in-depth PoC. The results showed YMatrix excelled in ingestion and query performance (especially complex queries) and compression ratio. YMatrix was ultimately chosen as the unified production-data platform for Phase I deployment.

Per the plan, Farasis Energy now routes traceability-related data—process, maintenance, materials, rework, barcode linkage, raw materials, workflows, module repairs, cell processes, module processes, and pack processes—into the warehouse for processing. This achieves full production-flow data consolidation and robustly supports end-to-end cell-production traceability.

Beyond performance, YMatrix delivered compression far beyond expectations. For the same production-line datasets, the storage footprint is just one-tenth of the original.

Farasis Energy’s production lines are highly digitalized and run dozens of business systems—but those systems sit on different databases and don’t interconnect. For example, PLM stores master production data; production data sits in Oracle; ERP runs on SAP HANA; WMS uses SQL Server; and QMS uses MySQL.

Before 2022, most data served on-site and managerial use cases. Process control and real-time monitoring were strong, but without data consolidation—or with insufficient database performance—the company couldn’t perform deep, multi-dimensional analysis or take a longer historical view for strategic insights.

With the lakehouse in place, standardized data combined with YMatrix’s powerful analytics unlocks much more value: intelligent cameras detect electrode-sheet defects in 0.02 seconds; wireless I/O modules collect real-time signals from 2,000+ sensors; and end-to-end smart-manufacturing data lands—via the IoT middle platform—on the enterprise data foundation. Traditional SPC analysis now draws from cleansed, aggregated sources. With curated data models and datasets, users self-serve the metrics they care about—making data use more customized and precise.

By pairing standardized data planning with programmatic implementation, Farasis Energy inventories and tiers its data assets, defines metrics and collections, aggregates data by defined paths, advances domain-driven data mining, and builds data-assisted decision-making—significantly elevating digital-operations maturity.

Anchored by YMatrix, Farasis Energy has built a unified data backbone that integrates multiple business systems and data sources. Through systematic data usage and integration, the group now has an always-on, panoramic data capability—forming a solid foundation for its ambitious smart-manufacturing blueprint.

Looking ahead, Farasis Energy will continue investing in data granularity, real-time capabilities, and completeness—delivering more real-time, precise, scientific, and intelligent management of production to boost efficiency. In parallel, it will further connect production data with OA, ERP, and other systems. With comprehensive, unified data, the company will gain higher-altitude insights for stronger decision support and improve cross-process collaboration across manufacturing and commercial operations.